Water Towers

New York City Water Towers

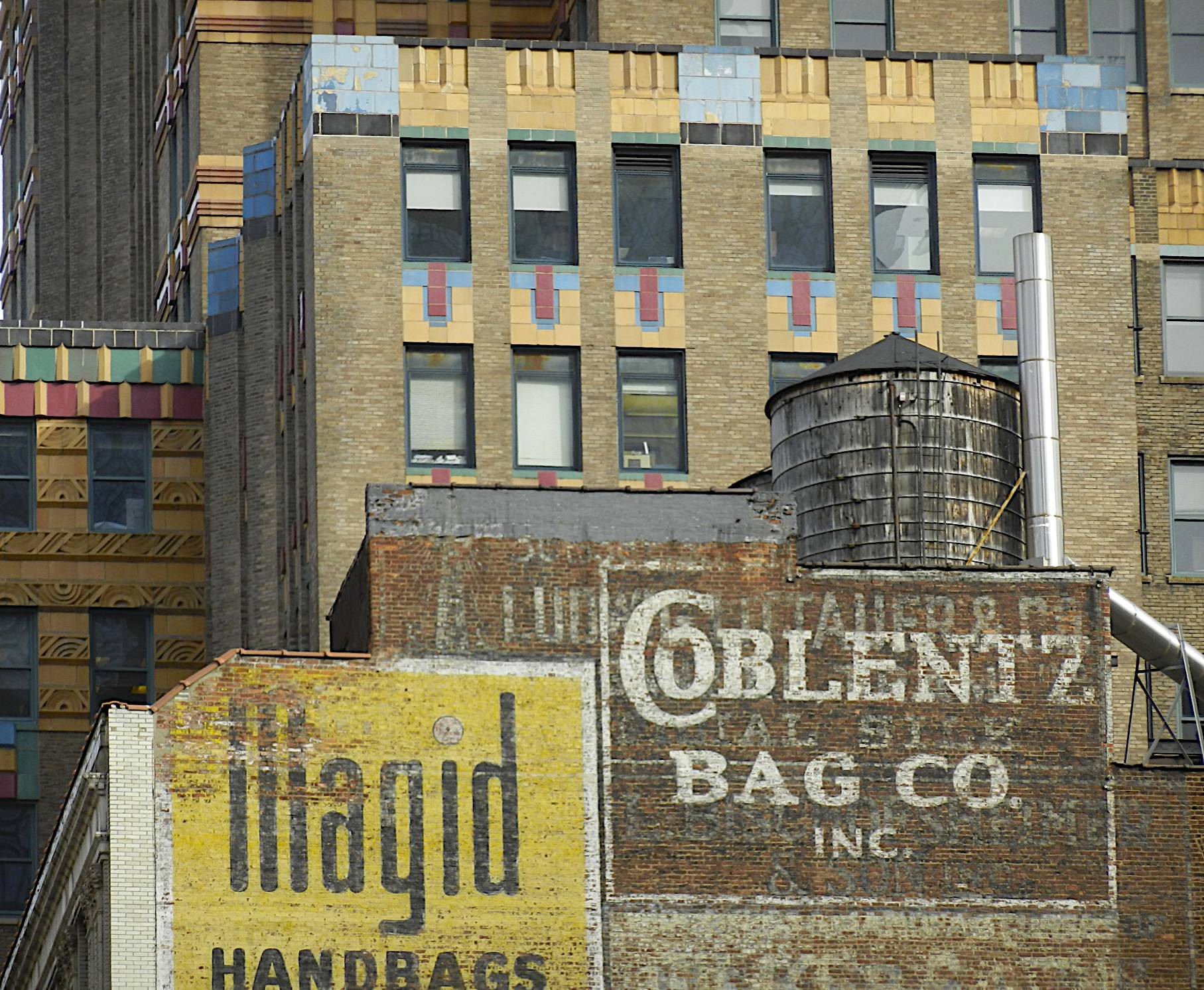

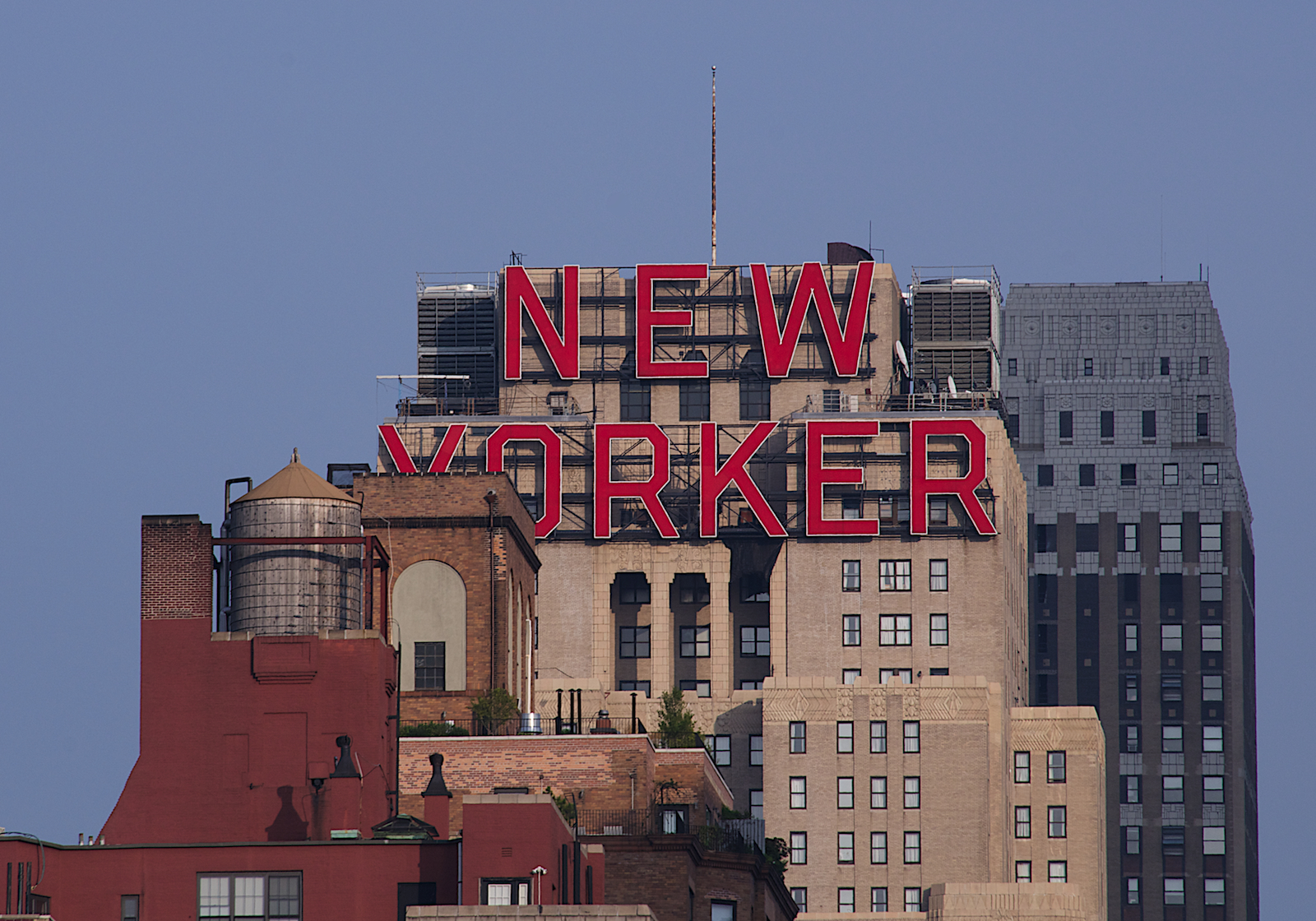

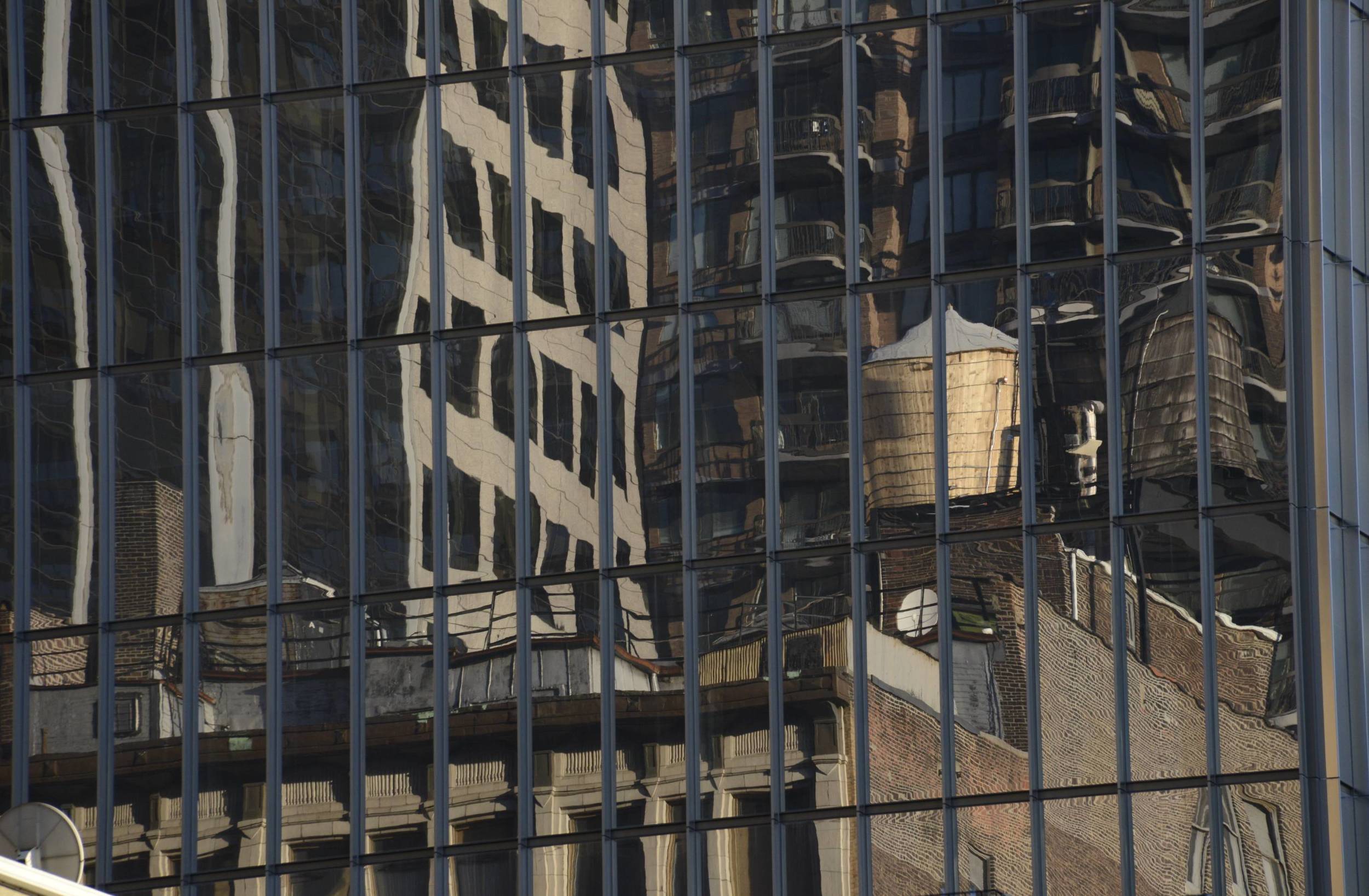

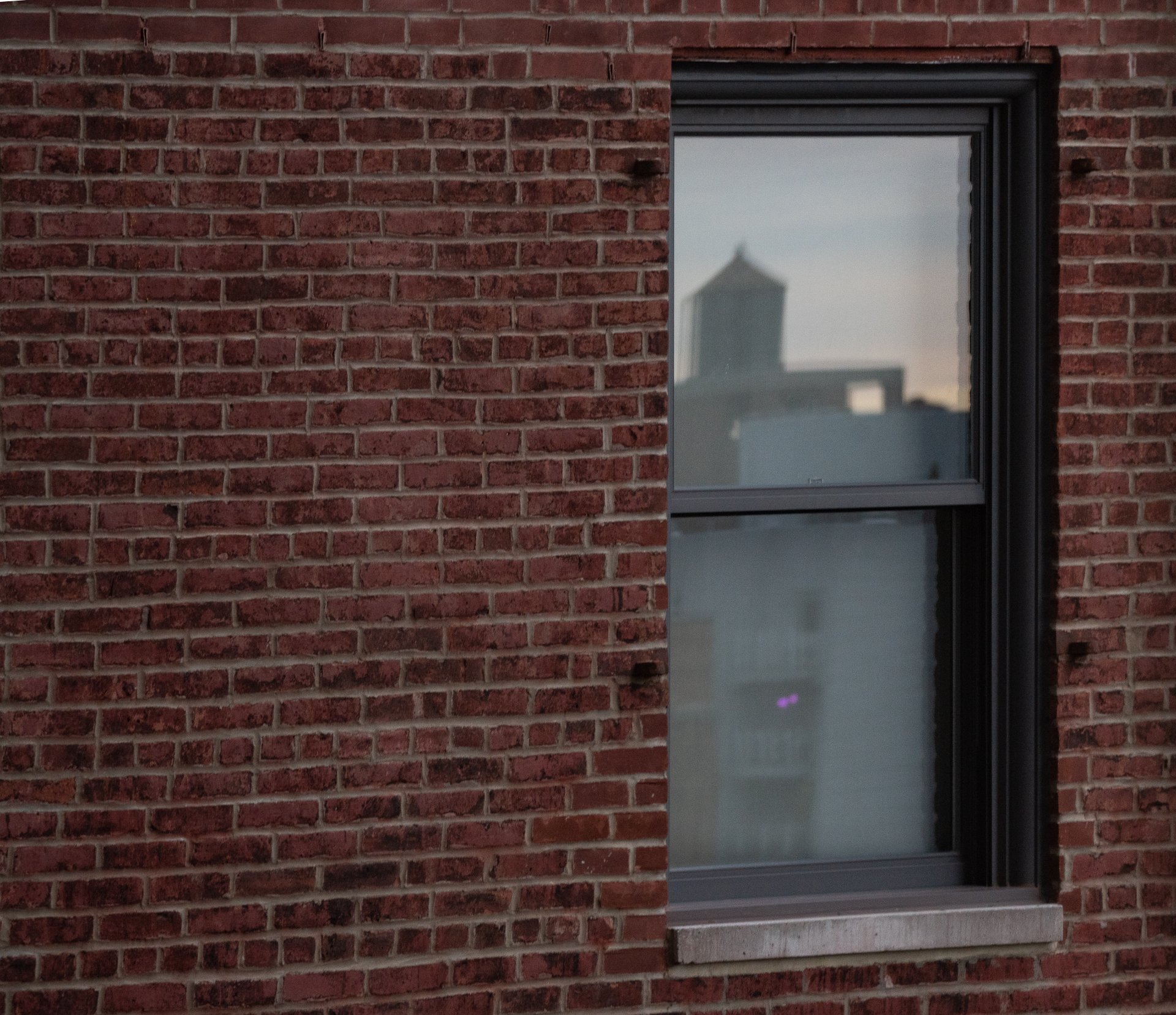

These images of the water towers in New York City are not only an tribute to these iconic structures in the city landscape, but also an excuse to explore hidden details and jewels of the New York City architecture.

This is an unique opportunity for me to experiment with shapes, form and texture, that are a frequent component of my photography journey.

In the 19th century, New York City required that all buildings higher than six stories be equipped with a rooftop water tower. This was necessary to prevent the need for excessively high pressures at lower elevations, which could burst pipes. Pressure in the city’s pipes will take water up only about half a dozen stories, so a building taller than just a few floors requires either a pumping system or a system of tanks. A water tower also provides emergency storage for fire protection.

Even today, no sealant is used to hold the water in. The wooden walls of the Water Tower are held together with cables but leak through the gaps when first filled. As the water saturates the wood it swells, the gaps close and become impermeable.

The rooftop water towers store 25,000 to 50,000 litres of water until it is needed in the building below. The upper portion of water is skimmed off the top for everyday use while the water in the bottom of the tower is held in reserve to fight fire. When the water drops below a certain level, a pressure switch, level switch or float valve will activate a pump or open a public water line to refill the water tower.

For over a century, the basic design of these tanks, which are essentially giant wooden barrels, has gone largely unchanged.

Installing, maintaining and replacing wooden water tanks in the city is largely handled by three companies: Isseks Brothers, the Rosenwach Group and American Pipe and Tank. Pressure in the city’s pipes will take water up only about half a dozen stories, so a building taller than just a few floors requires either a pumping system or a system of tanksThe changes in water-tank construction over the past 100 years, Mr. Hochhauser said, have amounted to little more than the introduction of power tools, and perhaps the movement to sell the cedar from the discarded old tanks (they last about 30 years) to hip furniture makers specializing in reclaimed wood.

Water tanks for buildings can also be made of steel, but they are less recognizable because they are mostly enclosed — imagine how hot a steel vat would get on a rooftop in August, or how quickly it might freeze on a January night. Wood does very well outside.

Flickr link: http://www.flickr.com/photos/93276562@N07/sets/72157633887522137/